shaft furnaces

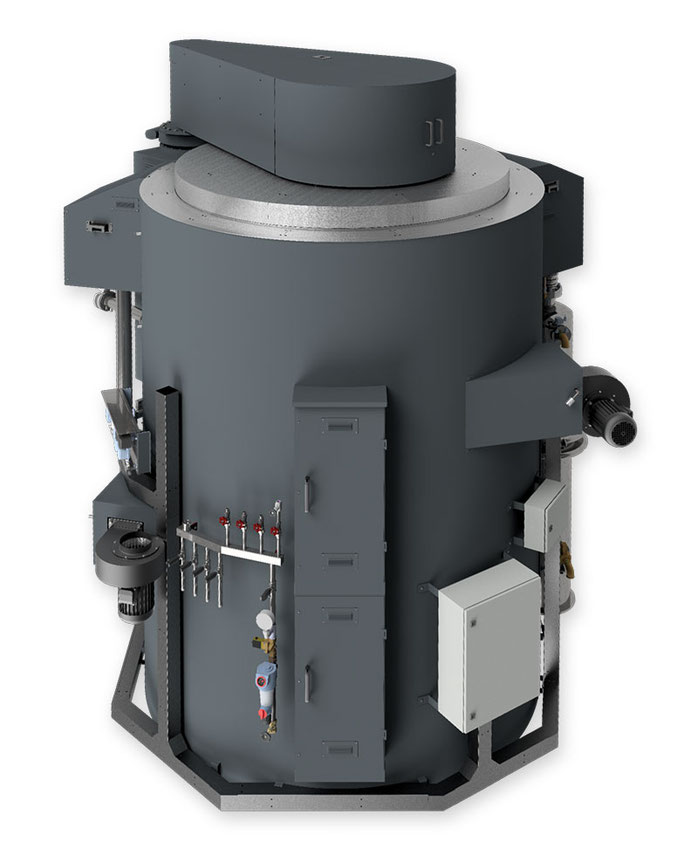

SL/SLG/SLS/SGK/SGN

shaft furnaces

Today shaft furnaces for heat treatment are used in electric or gas-heated versions. We supply shaft furnaces for various heat treatment processes with effective lengths of over 10,000 mm and diameters up to 5,000 mm.

The advantages: The furnaces can be loaded directly by crane. The furnace shafts are usually retractable, which means the required crane-hook-height is low. The vertical treatment of long components minimizes changes in dimensions and shape. Convection by means of circulation and a gas guide cylinder achieves a high heating and cooling rate with uniform heat transfer to the components.

vertical solutions for massive workpieces

Shaft furnaces are perfect for large or long parts that are treated vertically—with high load capacity and evenly heating.

The result: precise heat treatment with high load capacity and dimensional stability.

ease of use

easy opening and closing of the bonnet

homogeneity

even temperature distribution throughout the entire volume

automation

compatible with crane or loading equipment

technical specifications

Below you will find the most important technical details and advantages of our fully automated systems at one glance.

- heating type: electric or gas

- cooling: active or passive (via the combustion air fans)

- temperature distribution: via air circulation up to +/- 1.5 K

- design variants: single or double car

- atmosphere: air, nitrogen, other media

- program controller: Stange, PE, Siemens, Jumo

- fumigation: separate gasing cabinet, ammonia splitter

- processes: hardening, annealing, tempering, nitriding

- charging: by crane, semi-automatic or fully automatic

- lid types: by crane or lifting device

- door mechanism: : manual, hydraulic, or electric motor

- sizes: from 2 m³

- design variants: with or without retort

- temperatures: up to 1,100°C

- insulation: : solid or lightweight construction

advantages of our fully automated systems

maximum efficience

Our fully automated systems ensure maximum productivity and fast processing time.

flexibel process adaption

Our systems are individual configurable for tonnages and processes.

complete solution from one single source

All aditional components as a charging trolley for example are included.

future-proofed and reliable

State-of-the-art control, interfaces and a warranty up to 5 years.

optimize your industrial processes now

Do you plan a new production line or do you like to automate your existing furnace?

FAQ

What processes are possible?

Depending on the equipment: hardening, annealing, tempering, gas carburizing and nitriding.

How are long components handled and how does this affect dimensional accuracy?

Thanks to vertical handling and a recessed shaft construction, there are only minimal changes and dimension and shape.

How is the loading carried out and what kind of mechanism do the doors/lids have?

It’s possible do load by crane, semi-automaticlly or ful automaticlly ; lid or door mechanical, hydraulic, or electric motor-driven.

Up to what temperatures and in what construction volume are shaft furnaces available?

Temperatures up to approx. 1,100 °C are possible. TheConstruction sizes come in many variants, often from approx. 2 m³ upwards. Effective length from over 10,000 mm and Ø up to ~5,000 mm can be realized.