fully automated systems for heat treatment

Fully automated industrial furnaces

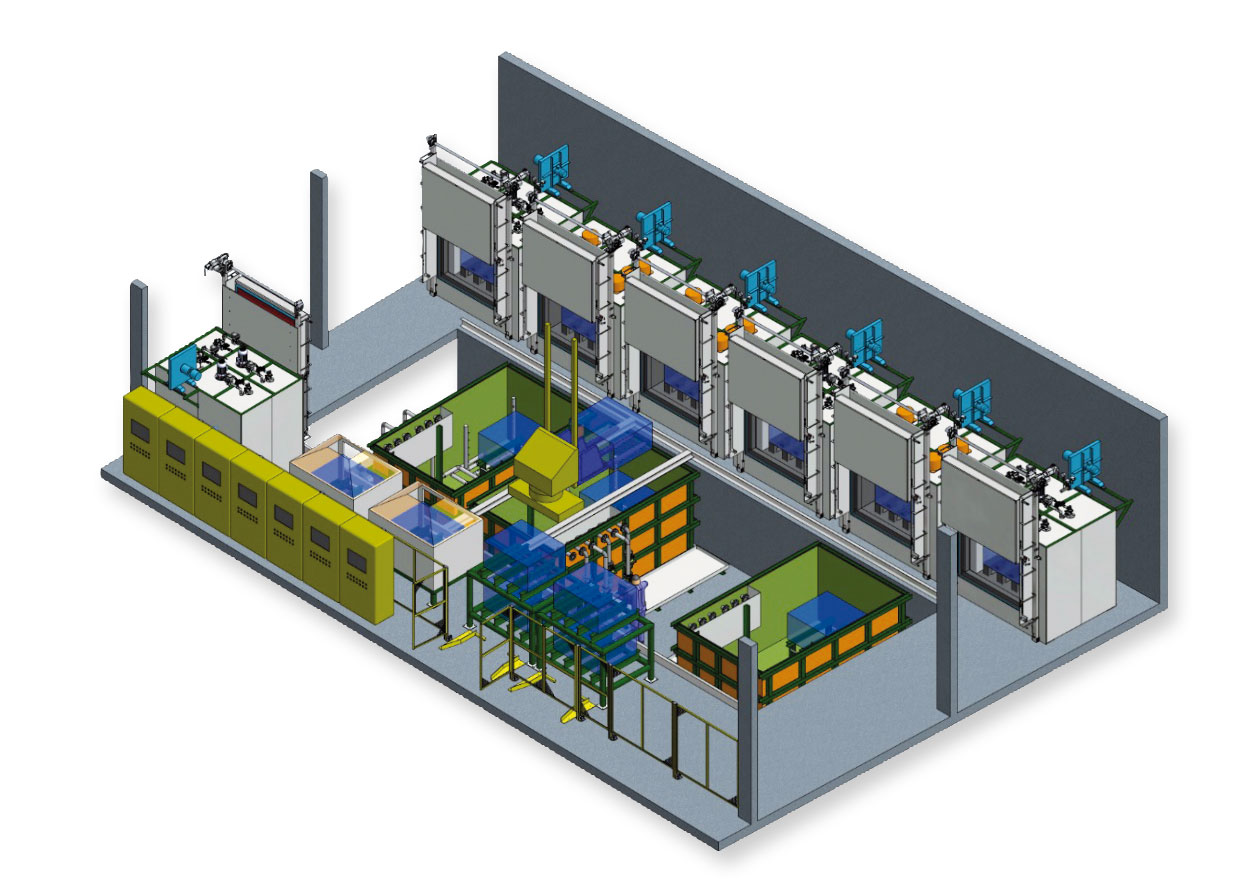

Our fully automated systems offer maximum efficiency, flexibility, and process reliability in heat treatment. Whether for small tonnages with short cycle times or large tonnages with customized process sequences, we develop tailor-made systems that perfectly match your requirements.

The systems can be implemented on the basis of our chamber, stove cart or shaft furnaces. Thanks to the modular design, capacities and processes can be scaled individually, from a single installation to complete production lines.

Trust and quality: We offer up to a 5-year warranty on our industrial furnaces, a clear commitment to the quality, reliability, and durability of our systems.

complete solutions from a single source

Our fully automated systems do not only include the furnace technology, but all relevant additional components, such as charging cars, crane systems, protective enclosures, cooling equipment, and much more as on your request.

The result: An overall concept that’s ensuring smothly processes in your production.

charging trolleys or crane systems

Efficient loading for fast and smooth production processes.

protective enclosures

Ensure maximum safety and protection for your employees.

cooling systems

Ensure controlled cooling and consistent process quality.

technical specifications

Below you will find the most important technical details and advantages of our fully automated systems at one glance.

- process: all common heat treatment processes

- charging: : horizontal and vertical

- sizes: from 2 m³

- control: flexible or fixed sequence

- warranty: up to 5 years on industrial furnaces

- interfaces: compatible with all common data systems

advantages of our fully automated systems

maximum efficience

Our fully automated systems ensure maximum productivity and fast processing time.

flexibel process adaption

Our systems are individual configurable for tonnages and processes.

complete solution from one single source

All aditional components as a charging trolley for example are inlcuded.

future-proofed and reliable

State-of-the-art control, interfaces and a warranty up to 5 years.

optimize your industrial processes now

Do you plan a new production line or do you like to automate your existing furnace?

FAQ

Welche Wärmebehandlungsverfahren können in den vollautomatisierten Anlagen durchgeführt werden?

Unsere Anlagen unterstützen alle gängigen Wärmebehandlungsverfahren, von Nitrieren über Anlassen bis zum Glühen, und können individuell auf Ihren Prozess abgestimmt werden.

Kann die Chargierung horizontal und vertikal erfolgen?

Ja, unsere Anlagen bieten sowohl horizontale als auch vertikale Chargierung, je nach Anforderung und Werkstückgröße.

Ab welchen Baugrößen sind die Anlagen verfügbar?

Unsere vollautomatisierten Systeme starten ab 2 m³ und lassen sich modular für größere Produktionskapazitäten erweitern.

Welche Steuerungsoptionen und Schnittstellen sind verfügbar?

Die Anlagen können mit flexibler oder starrer Abfolge betrieben werden und sind kompatibel mit allen gängigen Datenerfassungssystemen.