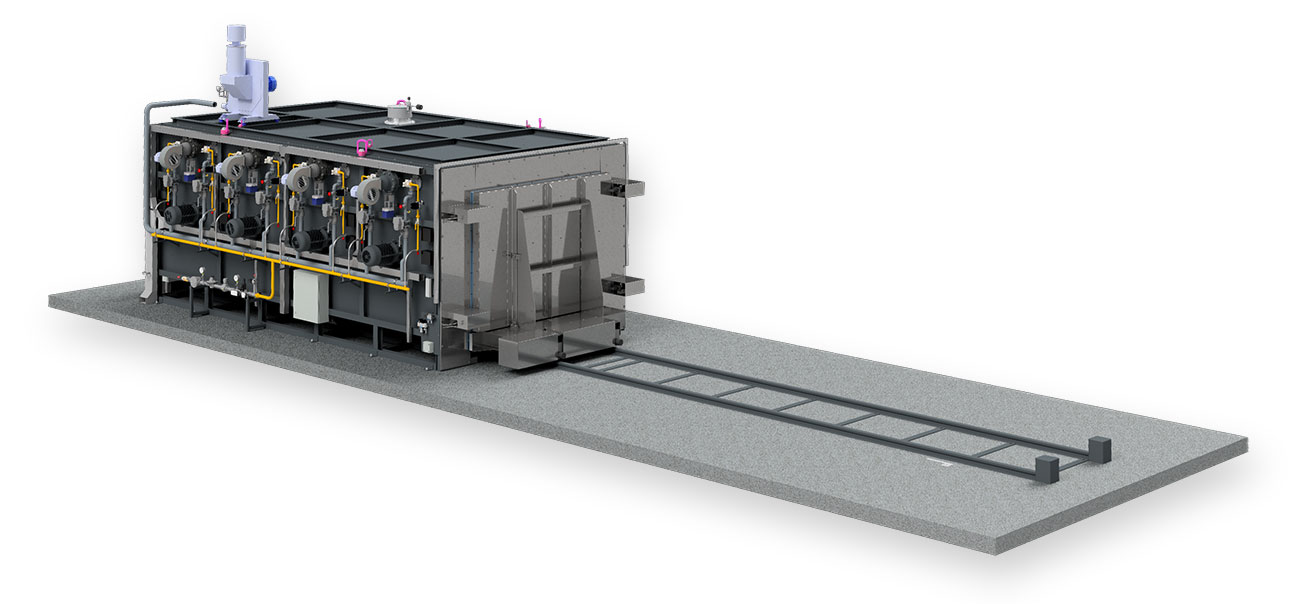

stove cart furnaces KLW/KLWG/KOW/KOWG

stove cart furnaces

Stove cart furnaces are a special type of chamber furnace and are particularly suitable for changing part sices. Normally the furnace bottom will be traveled by rails out of the furnace (most of the time). The batch is set up and moved into the furnace. Therefor batches can be changed in no time and residual heat can used in an energy-saving manner.

technical specifications

Below you will find the most important technical details and advantages of our fully automated systems at one glance.

- heating type: electric or gas

- cooling: active (via the combustion air blowers)

- Temperature distribution: via air circulation up to +/- 1.5 K

- atmosphere: air, nitrogen

- program controller: Stange, PE, Siemens, Jumo

- process: hardening, annealing, tempering, nitriding

- technical filling: by crane, by forklift, partially or fully automated possible

- door types: swing, parallel, lift door, or door on trolley

- door mechanism: manual, pneumatic, hydraulic, or electricmotor

- sizes: from 2 m³

- design variants: single or double trolley

- temperatures: up to 1,300° C

- insulation: : solid or lightweight construction

easy handling of heavy batches

Stove cart furnaces allow convenient loading of large and heavy workpieces thanks to movable cars.

Result: Safe and ergonomic working with high productivity.

ergonomics

convenient loading and unloading thanks to movable cars

accessibility

free access to all workpieces

safety

mechanical and thermal protection systems can be integrated as an option

advantages of our fully automated systems

maximum efficience

Our fully automated systems ensure maximum productivity and fast processing time.

flexibel process adaption

Our systems are individual configurable for tonnages and processes.

complete solution from one single source

All aditional components as a charging trolley for example are included.

future-proofed and reliable

State-of-the-art control, interfaces and a warranty up to 5 years.

optimize your industrial processes now

Do you plan a new production line or do you like to automate your existing furnace?

FAQ

How does loading/unloading with a trolley work?

The furnace floor / trolley can be pushed and pulled in and out on rails, while the batch is placed on the trolley. This enables an easy handling and saves time.

What kind of door mechanisms are available?

Doors are available as swing, parallel and lift ones, or placed on the trolleys; mechanical (manual) or with a pneumatic, hydraulic, or electric motor assistance.

What are the maximum temperatures for hearth furnaces?

Up to approx. 1,300 °C, depending on the model.

How efficient is the energy use?

Energy consumption is reduced through good insulation (solid or lightweight construction), residual heat utilization (when the trolley is outside), and optimized air flow.