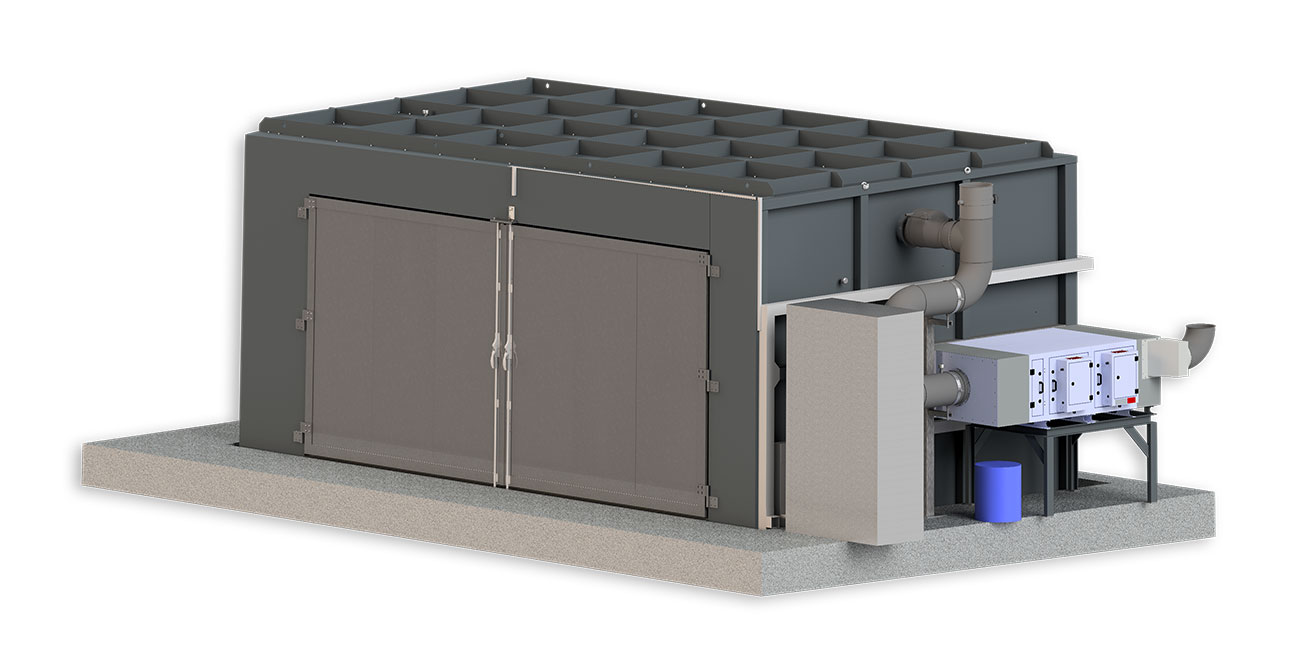

chamber furnaces KL/KLg/KO/KOg

chamber furnaces

The chamber furnace is one of our best-selling furnaces and includes two key features: it’s made of robust steel that‘s indestructible and delivers a consistent, reproducible temperature level. Of course internal racks or loading carts are tailored precisely to the requirements of the production needs.

technical data

Below you will find the most important technical details and advantages of our fully automated systems at one glance.

- heating type: : electric or gas

- cooling: active or passive (via the combustion air fans)

- temperature distribution: : via air circulation up to +/- 1.5 K

- atmosphere: air, nitrogen, others

- program controller: Stange, PE, Siemens, Jumo

- processes: hardening, annealing, tempering, nitriding

- technical filling: partially or fully automated, by crane or forklift

- door types: partially or fully automated, by crane or forklift

- door mechanism: manual, pneumatic, hydraulic, or electric motor

- sizes: up to 100 m³ usable space – up to 400 t batch weight

- design variants: with or without retort – fully automated on request

- temperatures: up to 1,300°C

- insulation: solid or lightweight construction

diverse control in a small size

Chamber furnaces enable precise temperature control and an evenly heat distribution – ideal for research, small series production, and special processes.

The result: reproducible results and consistent quality of components with a small space requirement.

precision

exact control of temperature and atmosphere

flexibility

adaptable to a wide variety of heat treatment processes

compactness

small space requirements with high performance

advantages of our fully automated systems

maximum efficience

Our fully automated systems ensure maximum productivity and fast processing time.

flexibel process adaption

Our systems are individual configurable for tonnages and processes.

complete solution from one single source

All aditional components as a charging trolley for example are included.

future-proofed and reliable

State-of-the-art control, interfaces and a warranty up to 5 years.

optimize your industrial processes now

Do you plan a new production line or do you like to automate your existing furnace?

FAQ

How homogeneous is the temperature distribution?

The temperature sensitivity of the chamber furnaces is ± 1.5 K thanks to optimized air circulation, which enables reproducible heat treatment in large volume.

What about the loading capacities?

Depending on the model: the chamber furnaces can be loaded up to 400 tons.

What atmospheres can the furnace provide?

Atmospheres such as air and nitrogen are possible, and depending on the equipment, other media are also possible.

What about the delievery time of a chamber furnace?

Since the KL/KO series is based on standardized models, delivery times can be reduced other than for custom-made products. (The exact delivery date depends on the model and equipment).