gas carburizing furnaces

SGK/SGKG/KGK/KGKG

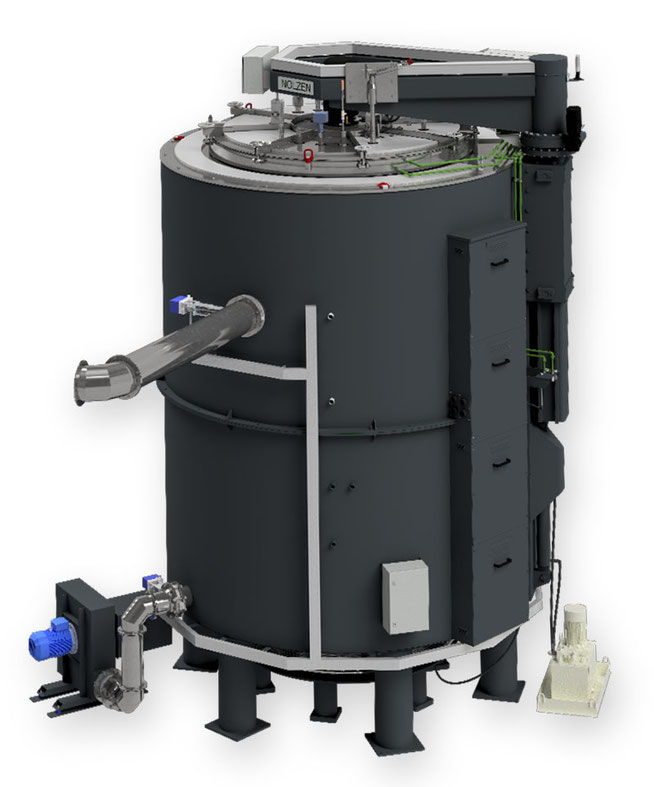

gas carburizing furnaces

Our gas carburizing furnaces can be designed for a retort temperatures of up to 1050°C.

We can design two types of gas carburizing furnaces: The classic design with a suspended retort, which is usually used for smaller batch weights, or the vertical one, in which the batch is placed in the base and the retort is sealed to the floor with a compensator. This allows for high batch weights.

In addition to manufacturing the furnaces, we also supply you with the complete switch and control technology, fumigation equipment and an analysis station on request.

surface hardening with maximum control

Our furnaces enable a precise control oft he gas atmosphere for a targeted carburization of component surfaces.

The result: a hard surface with a tough, dimensionally stable core.

atmosphere

precise gas control for a controlled carbon supply

process reliability

consistent results without distortion

integration

can be combined with quenching or cooling systems

technical specifications

Below you will find the most important technical details and advantages of our fully automated systems at one glance.

- heating type: electric or gas

- cooling: passive between retort and insulation, blowing or suction

- temperature distribution: via air circulation up to +/- 1.5 K

- atmosphere: carbonization atmosphere

- program controller: Stange, PE, Eurotherm

- fumigation:: separate gasing cabinet, ammonia splitter

- process: gas carbonization

- charging: : by crane, partially or fully automated

- lid types: hydraulic or electric motor

- door mechanism: pneumatic, hydraulic, or electric motor

- sizes: from 2 m³

- design variants: : with retort

- temperatures: up to 1,050° C

- insulation: solid or lightweight construction

advantages of our fully automated systems

maximum efficience

Our fully automated systems ensure maximum productivity and fast processing time.

flexibel process adaption

Our systems are individual configurable for tonnages and processes.

complete solution from one single source

All aditional components as a charging trolley for example are included.

future-proofed and reliable

State-of-the-art control, interfaces and a warranty up to 5 years.

optimize your industrial processes now

Do you plan a new production line or do you like to automate your existing furnace?

FAQ

Up to what temperatures can gs carburizing performing?

The furnaces are designed for temperatures up to 1,050°C.

What kind of design variants are available?

Classic hanging retorts or standing designs are available; e.g. this allows higher batch weights with the standing variant.

What loading/feeding options are available?

Batching via crane is possible; partially or fully automated.

What kind of characteristics regarding uniform insulation and temperature are available?

Insulation can be solid or lightweight; temperature distribution via air circulation up to +/- 1.5 K.