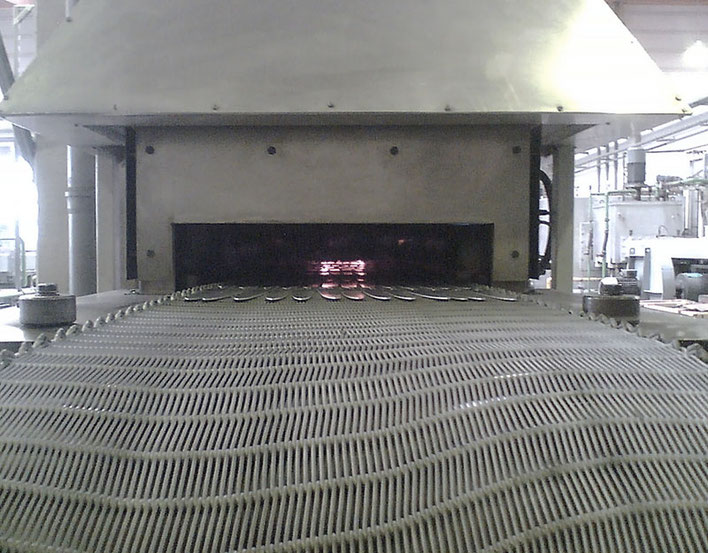

continuous furnaces

DL/DO/DLG/DO

continuous furnaces

Continuous furnaces are suitable for the heat treatment of bulk parts in a continuous process. If desired, the components can be complete loaded automatically. Both loading and unloading can be carried out using roller, chain, or belt conveyor systems.

technical specifications

Below you will find the most important technical details and advantages of our fully automated systems at one glance.

- heating type: : electric or gas

- cooling: active

- temperature distribution: up to +/- 3.0 K via air circulation

- atmosphere: air, nitrogen, hydrogen

- program controller: Stange, Siemens

- holding: fixed C-hooks, gondolas, chain link belt

- processes: hardening, annealing, tempering, nitriding

- charging: manual, semi-automatic or fully automatic

- sizes: from 2 m³

- temperatures: up to 1,050° C

- insulation: lightweight, solid brick line

continuous production without interruption

Continuous furnaces enable consistent processes for large quantities and constant processing time.

Result: High output by consistent product quality.

continuity

uninterrupted material flow

automation

low downtime thanks to automatic loading

process reliability

consistent temperature zones and control technology

advantages of our fully automated systems

maximum efficience

Our fully automated systems ensure maximum productivity and fast processing time.

flexibel process adaption

Our systems are individual configurable for tonnages and processes.

complete solution from one single source

All aditional components as a charging trolley for example are included.

future-proofed and reliable

State-of-the-art control, interfaces and a warranty up to 5 years.

optimize your industrial processes now

Do you plan a new production line or do you like to automate your existing furnace?

FAQ

What processes can be carried out in continuous furnaces?

Hardening, annealing, and tempering is possible.

How is loading and unloading carried out?

conveyor systems such as rollers, chains, or belts: fully automatic, semi-automatic or manuel

What are the available sizes and what temperatures can be reached?

Sizes from approx. 2 m³ and reachable temperatures up to approx. 1,050°C.

How precise can the temperature distribution be?

Depending in the design: temperature fluctuations are +/- 3 K , taking air circulation into account.