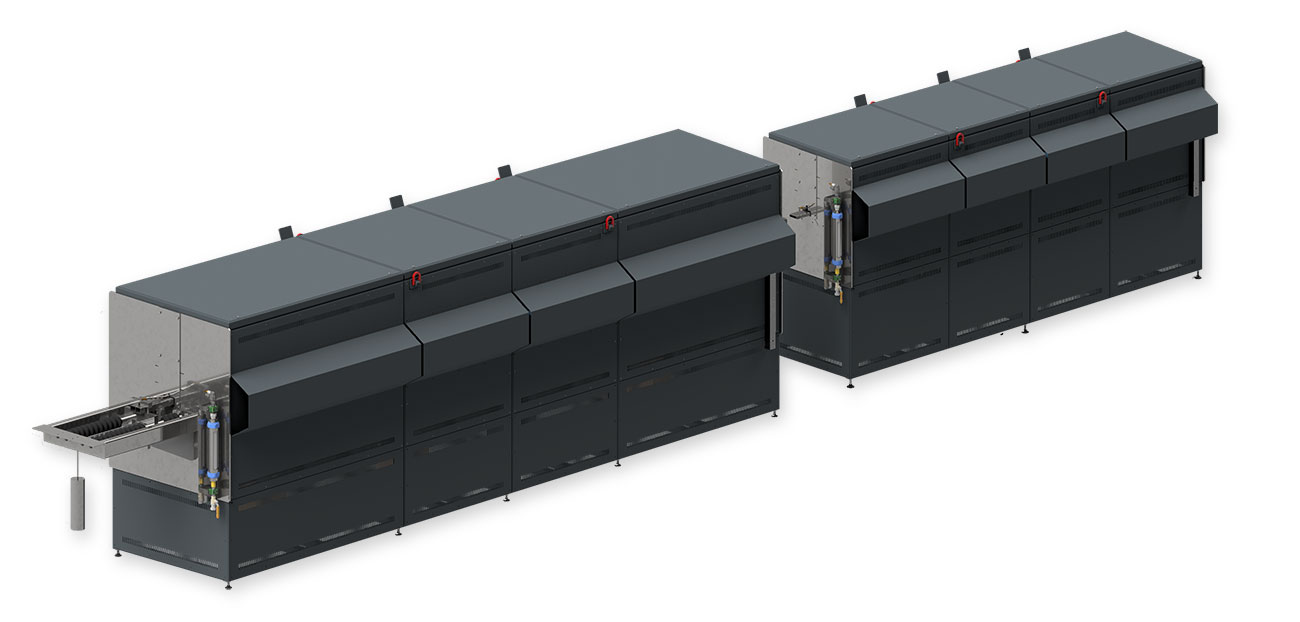

band saw pull-through systems

DO/DOG

band saw pull-through systems

Our band saw pull-through systems operate in a continuous process and are used to harden and temper band saws in a one step. We supply both complete heat treatment lines that are ready to plug in and individual components, depending on the application.

technical specifications

Below you will find the most important technical details and advantages of our fully automated systems at one glance.

- heating type: electric

- cooling: passive or heat exchanger

- temperature distribution: via air circulation up to +/- 3.0 K

- atmosphere: N2

- program controller: Stange, Siemens

- accommodation: horizontal or vertical belts

- process: gas carburizing

- charging: by crane, partially or fully automated

- lid shapes: Hydraulisch oder elektromotorisch

- Türmechanik: hydraulic or electric motor

- sizes: from 2 m³

- design variants: with retort

- temperatures: up to 1.050° C

- insulation: solid or lightweight construction

precise sawing in continuous operation

These systems are designed for high volumes and consistent cutting quality.

The result: consistent, precise cuts with minimal wear.

precision

stable belt running and controlled feed

cooling

automatic lubricant supply extends tool life

safety

enclosures protect staff and the surrounding area

advantages of our fully automated systems

maximum efficience

Our fully automated systems ensure maximum productivity and fast processing time.

flexibel process adaption

Our systems are individual configurable for tonnages and processes.

complete solution from one single source

All aditional components as a charging trolley for example are included.

future-proofed and reliable

State-of-the-art control, interfaces and a warranty up to 5 years.

optimize your industrial processes now

Do you plan a new production line or do you like to automate your existing furnace?

FAQ

What materials can be processed?

Steel, aluminum, special alloys, depending on the strip material.

How is the cooling process achieved?

Automatic supply of coolant or lubricant.

How high is the cutting precision?

High uniformity thanks to stable strip running and constant feed.

What safety precautions are available?

Protective housing and emergency shut-offs.