KL/KO/KLW/KOW series

KL/KO/KLW/KOW series

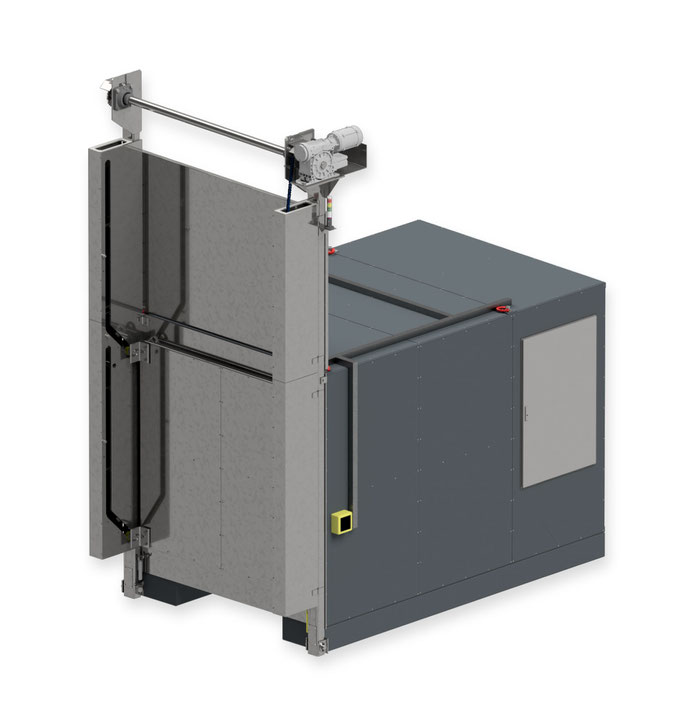

Based on our many years of experience in furnace construction we developed he KL and KO chamber furnace series and the KLW and KOW stove cart furnace series. A high quality, a mature concept and fast delivery times are just a few features to this furnace serie. Both the chamber furnace and stove cart furnace series can be manufactured in electric or gas-fired versions.

proven technology, that‘s configurable individually

Due to individual requirements, our standardized basic systems can be flexible adapted.

The result: Short delivery times and proven quality added by a full range of functions.

standardization

short delivery times and high reliability

modularity

customizable equipment and control systems

compatibility

evenly operating and control structure across all models

technical specifications

Below you will find the most important technical details and advantages of our fully automated systems at one glance.

- heating type: electric or gas

- cooling: activ or passiv (via the combustion air fans)

- temperature distribution: via air circulation up to +/- 1.5 K

- atmosphere: air, nitrogen, other media

- program controller: Stange, PE, Siemens, Jumo

- processes: hardening, annealing, tempering

- charging: by crane, by forklift, partially or fully automated

- door types: swing or lift door

- door mechanism: manual, pneumatic, hydraulic, or electric motor

- sizes: from 0.13 m³

- charging weight: up to 20 t

- temperatures: up to 1,300° C

- insulation: solid or lighweight

advantages of our fully automated systems

maximum efficience

Our fully automated systems ensure maximum productivity and fast processing time.

flexibel process adaption

Our systems are individual configurable for tonnages and processes.

complete solution from one single source

All aditional components as a charging trolley for example are included.

future-proofed and reliable

State-of-the-art control, interfaces and a warranty up to 5 years.

optimize your industrial processes now

Do you plan a new production line or do you like to automate your existing furnace?

FAQ

What heat treatment processes can be carried out in the fully automated systems?

Our systems support all common heat treatment processes, like nitriding, tempering and annealing and can be individually tailored to your processes.

Can charging be carried out horizontally and vertically?

Yes, our systems offer both horizontal and vertical charging, depending on requirements and workpiece size.

What is the minimum size of a system?

Our fully automated systems start at 2 m³ and can be expanded modularly for larger production capacities.

What control options and interfaces are available?

The systems can be operated with flexible or fixed sequences and are compatible with all common data acquisition systems.